Description

Container power plants are fully self-contained power modules based on diesel power plant, designed for operation in temperatures ranging from -50 ° C to + 50 ° C in the absence of electrical networks, or for backup - emergency power supply to consumers. Diesel generator in the container is protected from unfavorable weather conditions, which guarantees a long service life of the power plant. All power units are produced in three different climatic versions: "Standard", "North" and "Arctic"

Application area

Industrial facilities, medical facilities, communications and data transmission facilities, agricultural and industrial complexes with a continuous production cycle, as well as the areas away from the grid.

Functions

– Starting and stopping diesel power plant;

– Manual connection and disconnection of the generator load;

– Automatic disconnection of the load from the generator at any stop of AD;

– Manual change of the generator voltage;

– Manual adjustment of the generator drop;

– Emergency protection of AD (by stopping it), indication of the reason for the emergency situation.

Technical data – на for a diesel generator 60 kW ЯМЗ (АД-60-Т400), open construction

|

BASIC CHARACTERISTICS FOR DPP |

|

|

Prime power |

60 kW / 75 kVA |

|

Reserve capacity |

66 kW / 82.5 kVA |

|

Current type |

AC, 3-phase |

|

Rated frequency |

50 Hz |

|

Rated voltage |

400 V |

|

Rated current |

108 А |

|

Power factor, cos φ |

0,8 |

|

DPP application class according to GOST R 53987-2010 / ISO 8528-1: 2005 |

G2 (standard.) |

|

FUEL CONSUMPTION |

|

|

At 100% power |

18.0 l/h |

|

At 75% power |

13.7 l/h |

|

At 50% power |

9.6 l/h |

|

Power island from the built-in fuel tank, at 75% power |

14.5 hours |

|

Fuel efficiency – marginal costs for diesel fuel for 1000 kW*h of electric energy |

305.5 l |

|

REFILL CAPACITIES |

|

|

Fuel tank |

200 l |

|

Cooling system |

33 l |

|

Lubrication system |

21 l |

|

Batteries (AB) |

2 x 132 A*h |

|

ENGINE SPECIFICATIONS |

|

|

Engine model |

ЯМЗ-236М2-48 |

|

Country of Origin |

Russia |

|

Engine's type |

Diesel, 4-stroke |

|

Prime power |

132 kW |

|

Reserve capacity |

145,2 kW |

|

Engine capacity |

11,15 l |

|

Number, arrangement of cylinders |

6, V-shaped |

|

Cylinder bore/piston stroke |

130 х 140 mm |

|

Compression ratio |

16,5:1 |

|

Firing order |

1-4-2-5-3-6 |

|

Rated speed |

2100 min-1 |

|

Type of speed controller |

mechanical, without the support of CAN-bus |

|

Fuel Injection System |

direct injection, high-pressure fuel pump with a mechanical governor |

|

Type of boost air charging |

naturally aspirated (atmospheric) |

|

Cooling system |

liquid |

|

power takeoff to the fan |

5 kW |

|

load acceptance interval (step-load, G2), rel. main power |

% |

|

Rated voltage of the electrical system |

24 V |

|

Fuel rate3: |

|

|

at 100% of the rated power |

214 g/kW*h |

|

at 75% of the rated power |

0 г/g/kW*h |

|

at 50% of the rated power |

0 g/kW*h |

|

Burning oil consumption ratio (100% of the rated power): |

|

|

- with respect to fuel consumption |

0.5 % |

|

- absolute consumption |

0,09 l/h |

|

- specific consumption |

1,1 g/kW*h |

|

Standard period for engine oil change6 |

500 motor hours |

|

Engine cycle life |

10000 motor hours |

|

OTHER DPP EQUIPMENT |

|

|

Muffler |

Industrial muffler (noise damping level is12 -15 dBA), with bellow valves and a spark arrester |

|

Generator protection |

3-phase circuit breaker with shunt release device |

|

DPP control unit |

digital - at ComAp InteliLiteNT controller (Czech Republic) for motors without control support for CAN-Bus |

|

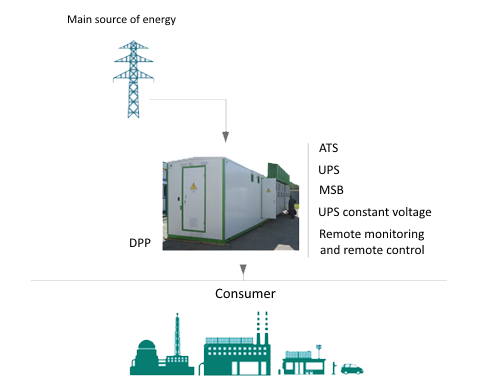

Automatic transfer switch (ATS) |

available (optional) |

|

DPP Parallel operation |

available (optional) |

|

Remote Monitoring and Control |

available (optional) |

|

Integration with an uninterruptible power |

available (optional) |

|

The degree of automation according to GOST R 53174-2008, GOST 14228-80 |

1, 2 or 3 (on the basis of the technical requirements of the Customer) |

|

Networking with "solidly earthed" / "isolated" neutral |

Available/available |

* Technical specifications and completing units can be changed in accordance with the technical requirements of the customer.

This information is introductory and can be changed without notice.